Tapping is an important process used to create internal threads in various materials such as metals and plastics. It involves the use of a tap which is a cutting tool with threaded grooves which produces accurate and reliable threads. Here are the key steps in the manufacturing tapping process.Material selection

The first step is to select the appropriate material. Different materials require specific tapping techniques and tools, so it is essential to consider factors like hardness, toughness and machinability.

Tap selection

Choosing the right tap is crucial for successful tapping. The tap’s size and thread type must match the required specifications of the internal threads. Common types of taps include hand taps, machine taps and spiral point taps.tapping machines can also be pneumatic or electric.

Hole preparation

Before tapping, the workpiece needs a properly sized and centred hole. It is crucial to use the appropriate drilling technique to avoid misalignment.

Lubrication

Applying a suitable cutting fluid or lubricant during tapping reduces friction, heat, and tool wear. It also helps evacuate chips from the threads, improving the overall efficiency of the process.

Tap alignment

Positioning the tap correctly is essential to achieve accurate threads as misalignment can lead to damaged threads or broken taps. Using tap guides can help ensure proper positioning.

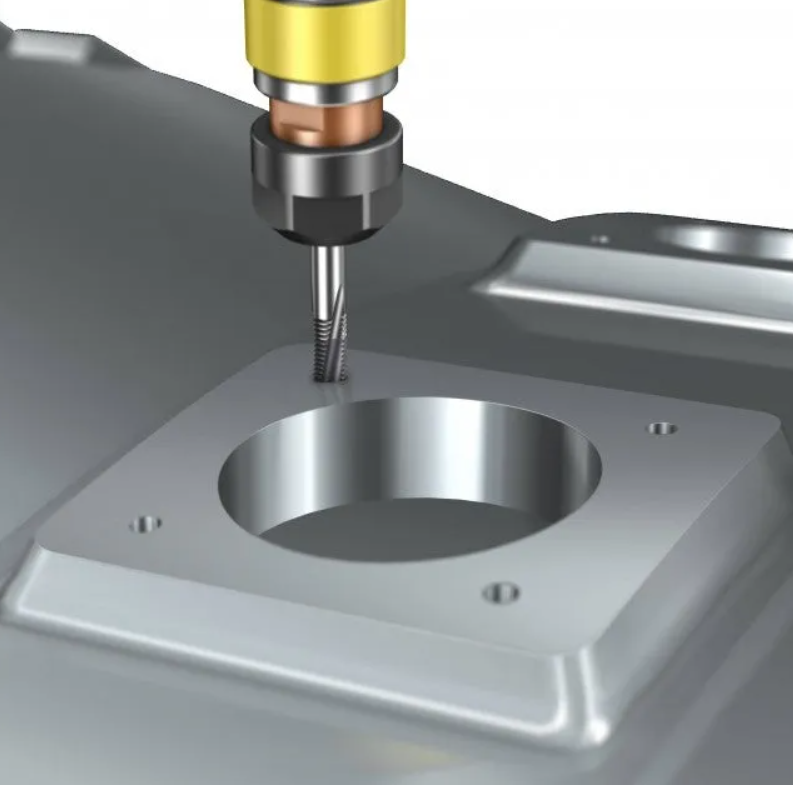

Tapping process

The tapping process itself involves rotating the tap into the workpiece to create the internal threads. For manual tapping, steady and consistent pressure must be applied, while machine tapping requires precise control over speed and feed rates. Higher-capacity tapping machines are frequently being developed to deal with modern manufacturing requirements.

Peck tapping

When dealing with deep holes or difficult-to-machine materials, peck tapping is often used. It involves retracting the tap periodically during the tapping process to clear chips and prevent tap breakage.

Inspection

After tapping, it is vital to inspect the threads for accuracy and quality. Thread gauges and visual inspection can be used to check the thread’s pitch, depth, and alignment.

In conclusion, understanding the key steps involved in manufacturing tapping is crucial for achieving high-quality threaded components.

Leave a Reply